At one of Stellantis’ busiest assembly plants, a new kind of coworker is quietly reshaping how work gets done.

An AI-powered inventory robot from Dexory now scans warehouse shelves in about 90 minutes. The same task previously took a human team roughly 280 hours. The difference is consistency, visibility, and a shift in how people spend their time, not just speed.

The robot operates inside Stellantis’ Sterling Heights Assembly Plant while nearly 7,000 workers build Ram 1500 trucks around it. Instead of clipboards and ladders, the robot glides through aisles, scans barcodes, projects light onto boxes, and builds a live digital map of inventory.

What the Robot Actually Does

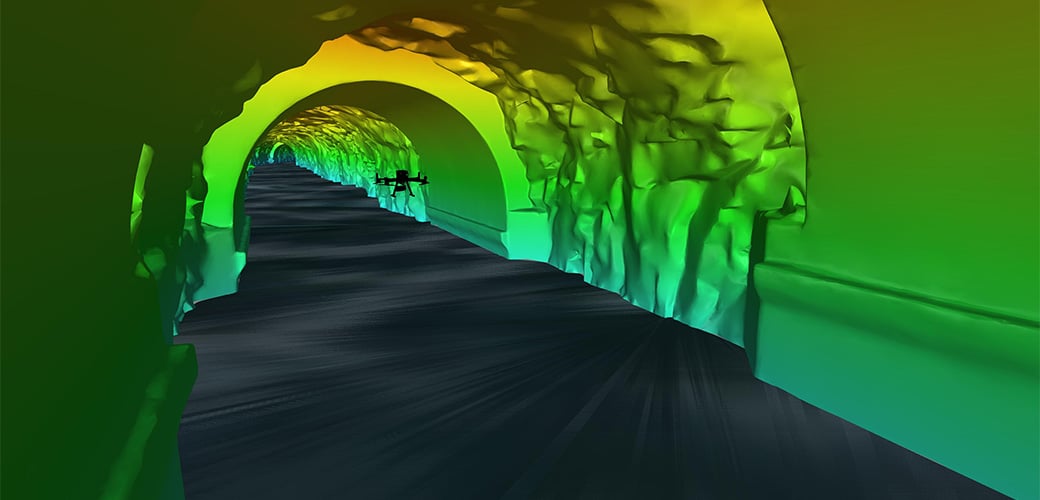

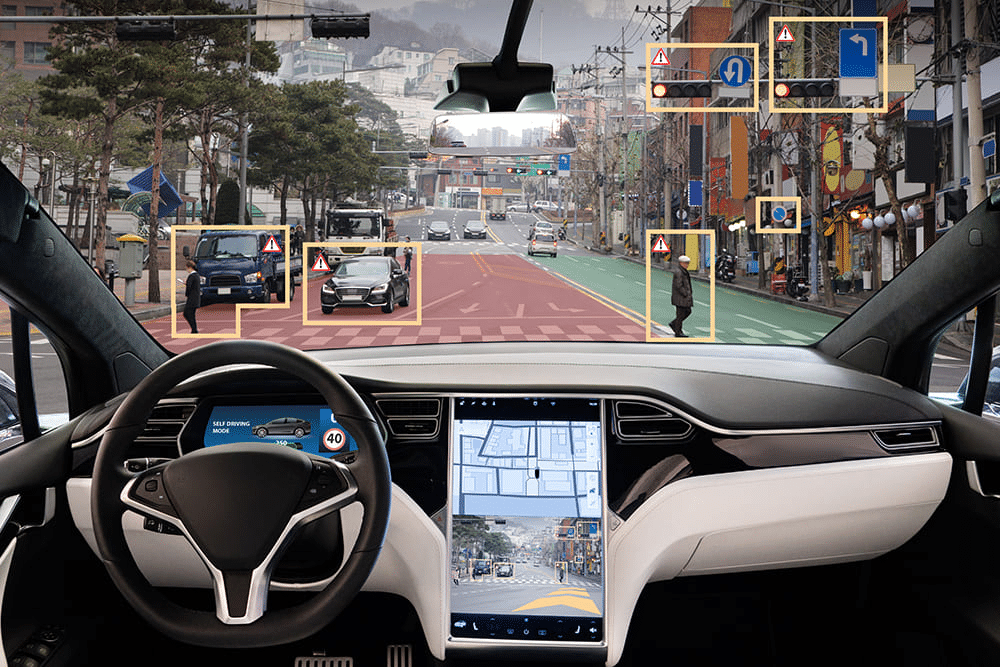

When idle, the Dexory robot stands about 11.5 feet tall. When scanning, it can extend upward to reach shelves as high as 46 feet. Cameras, barcode scanners, and LiDAR sensors work together to capture inventory data at a scale and pace humans simply cannot sustain.

The system can catalog more than 1,300 different small-box parts in just a few hours. These are components light enough for one person to carry, but numerous enough to create bottlenecks when tracked manually.

Plant managers report that parts are easier to locate, inventory accuracy improves, and workflows become more predictable. The robot does the same careful scan every time.

Automation Without Replacement

One of the most important parts of this story is what did not happen.

No layoffs followed the robot’s arrival. Workers who previously handled inventory scanning were reassigned to new roles inside the plant. The robot took over a repetitive, time-heavy task. People moved into work that required judgment, problem-solving, and coordination.

Stellantis leaders described the robot as something designed to work alongside teams, including union members, rather than replace them. In practice, the technology supports human work instead of competing with it.

Safety and Awareness Built In

Efficiency is only part of the value. Safety is another.

Because the robot continuously scans its environment, it can flag unstable pallets, overloaded shelves, or other hazards that might otherwise go unnoticed. During demonstrations, the robot stopped when a person stepped into its path and adjusted its movement to avoid low overhead obstacles.

This kind of situational awareness matters in large, busy facilities where small issues can quickly turn into bigger problems.

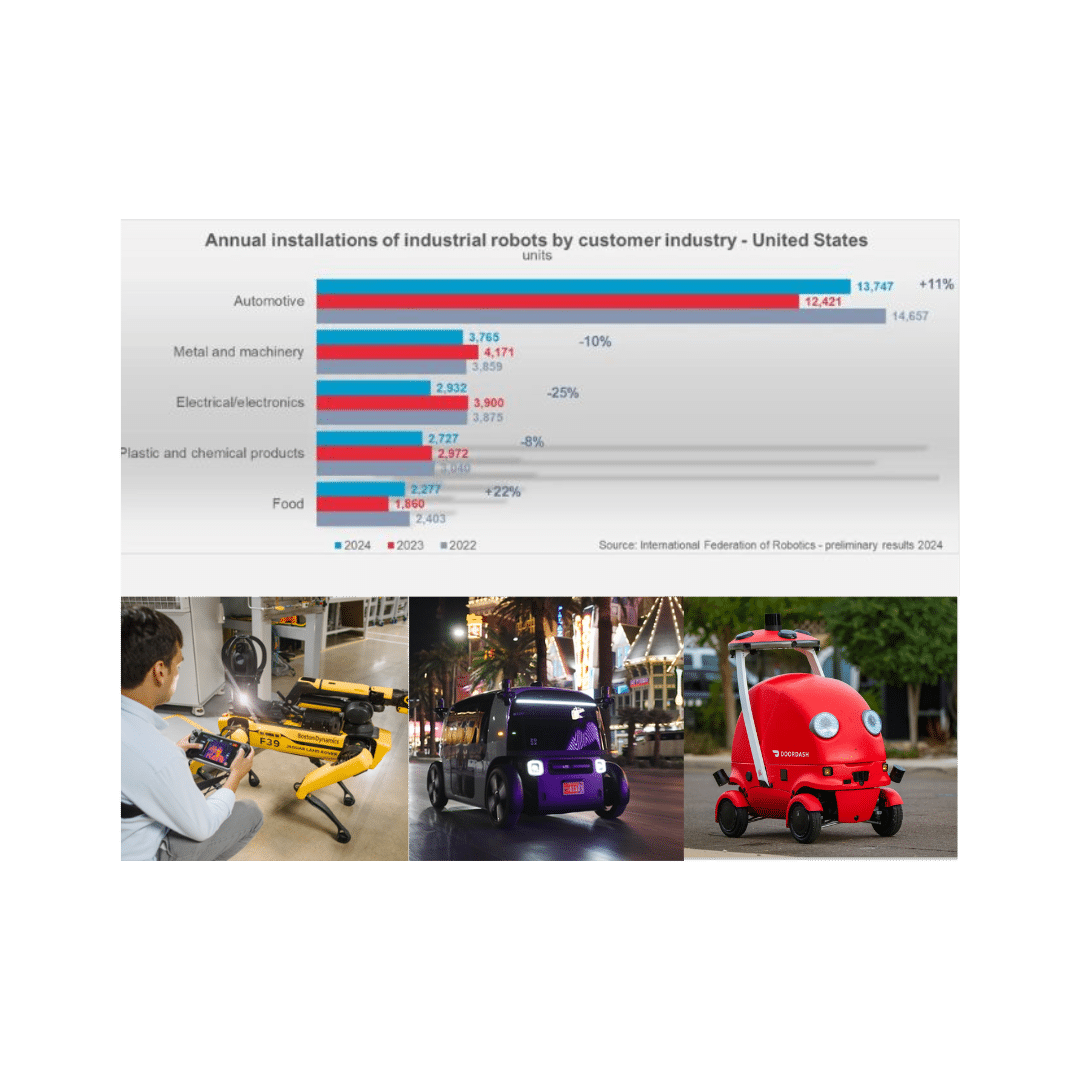

A Signal of What Is Coming

Stellantis is the first of the Detroit Three automakers to deploy this type of inventory scanning robot, but it will not be the last. Similar systems are already common in large e-commerce warehouses. Manufacturing is now catching up.

The takeaway is not that robots are getting faster. It is that work is being restructured. Tasks that depend on endurance and repetition are increasingly handled by machines. Tasks that depend on planning, thinking, and adapting stay with people.

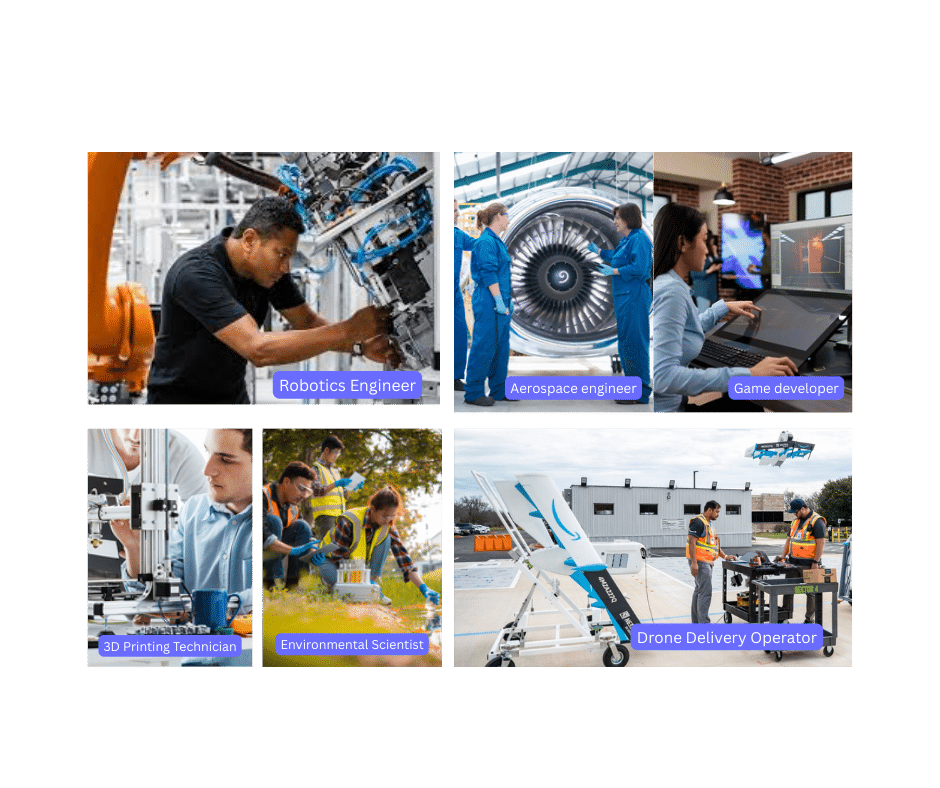

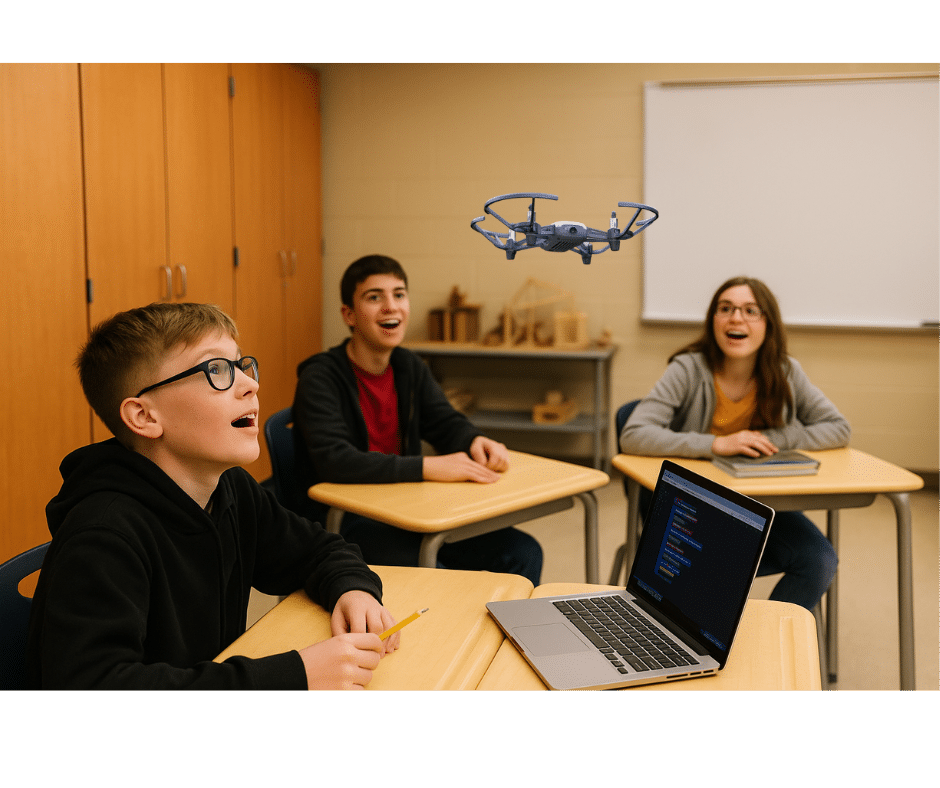

For educators, this matters. These are the environments students will eventually work in. Understanding robotics, sensors, autonomy, and human–robot collaboration is operational.

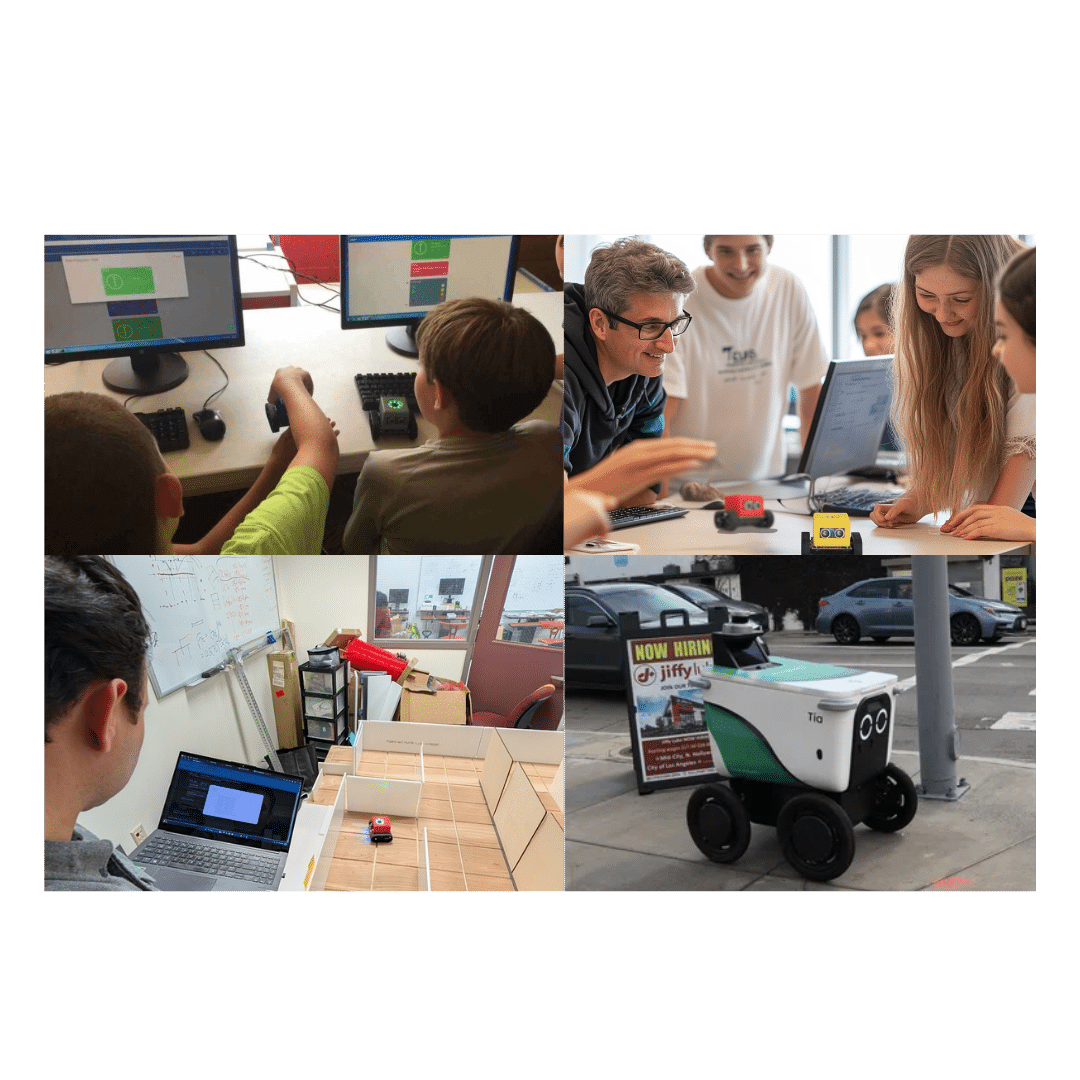

Where LocoRobo Fits In

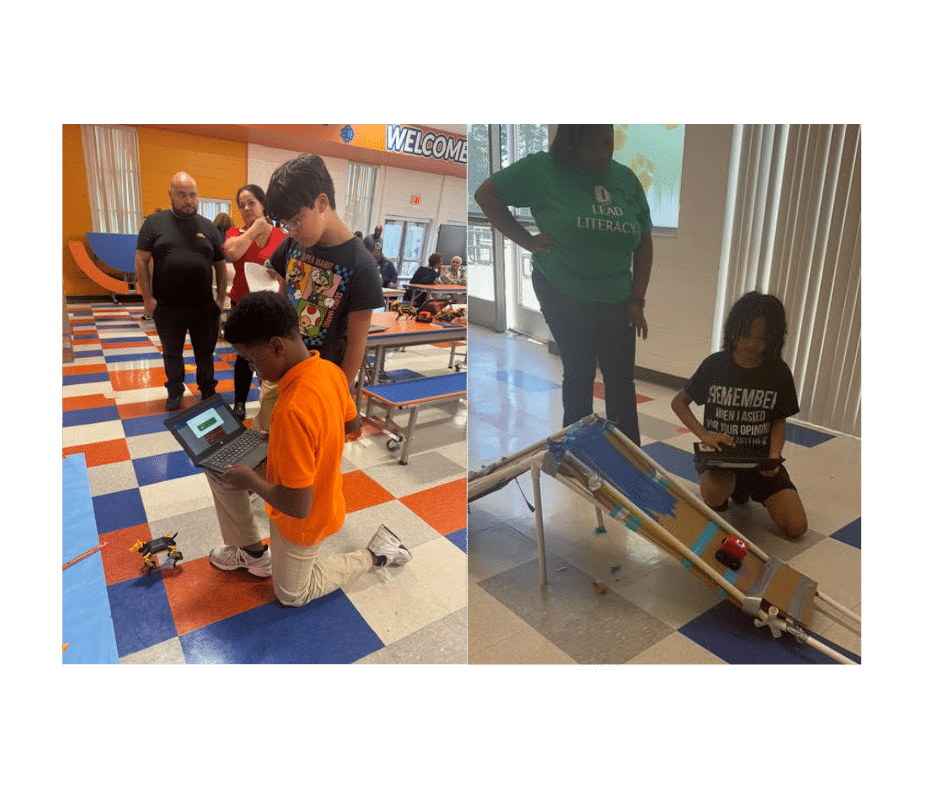

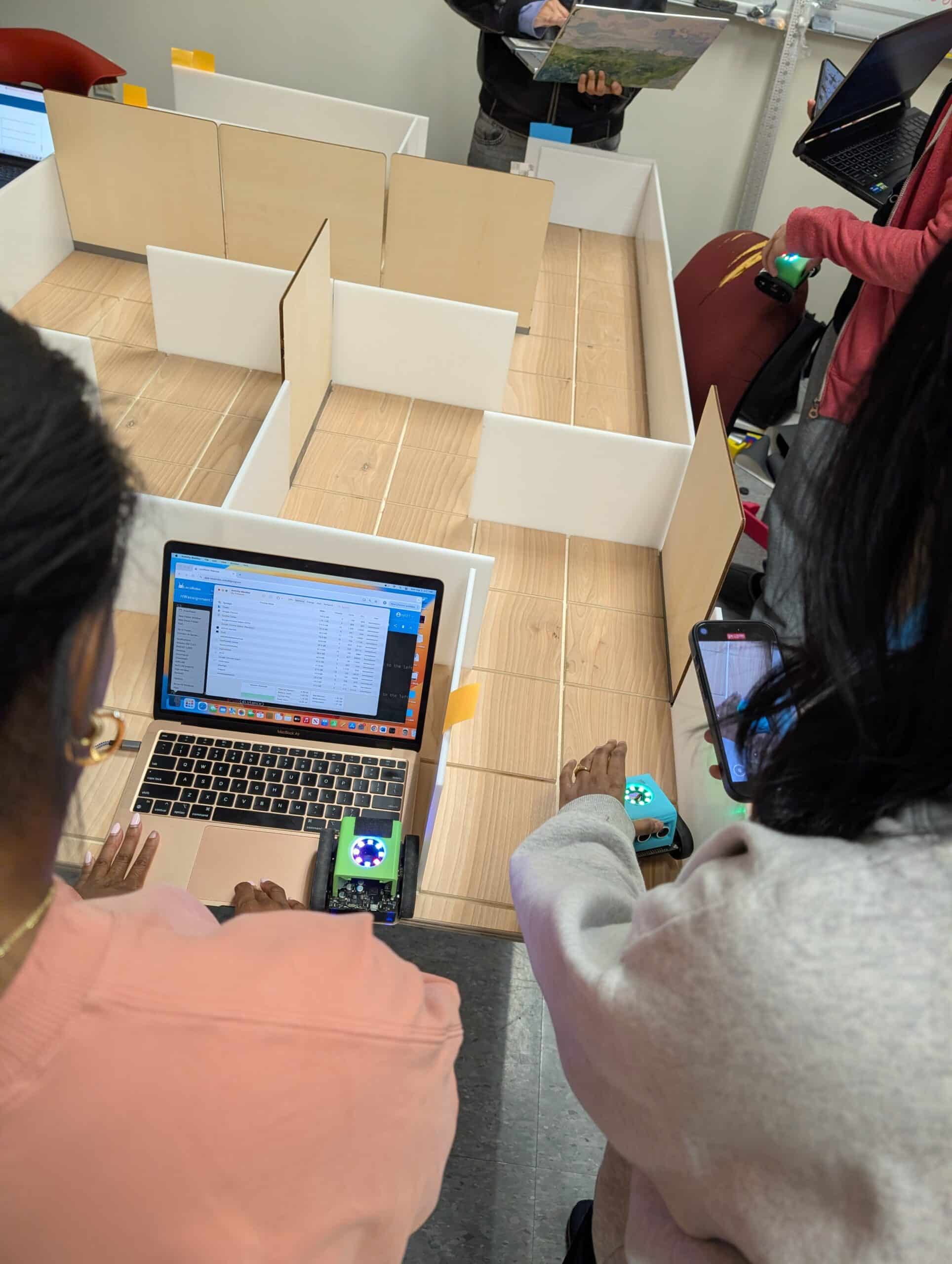

At LocoRobo, this is exactly the kind of real-world robotics application we design our K12 robotics solutions around.

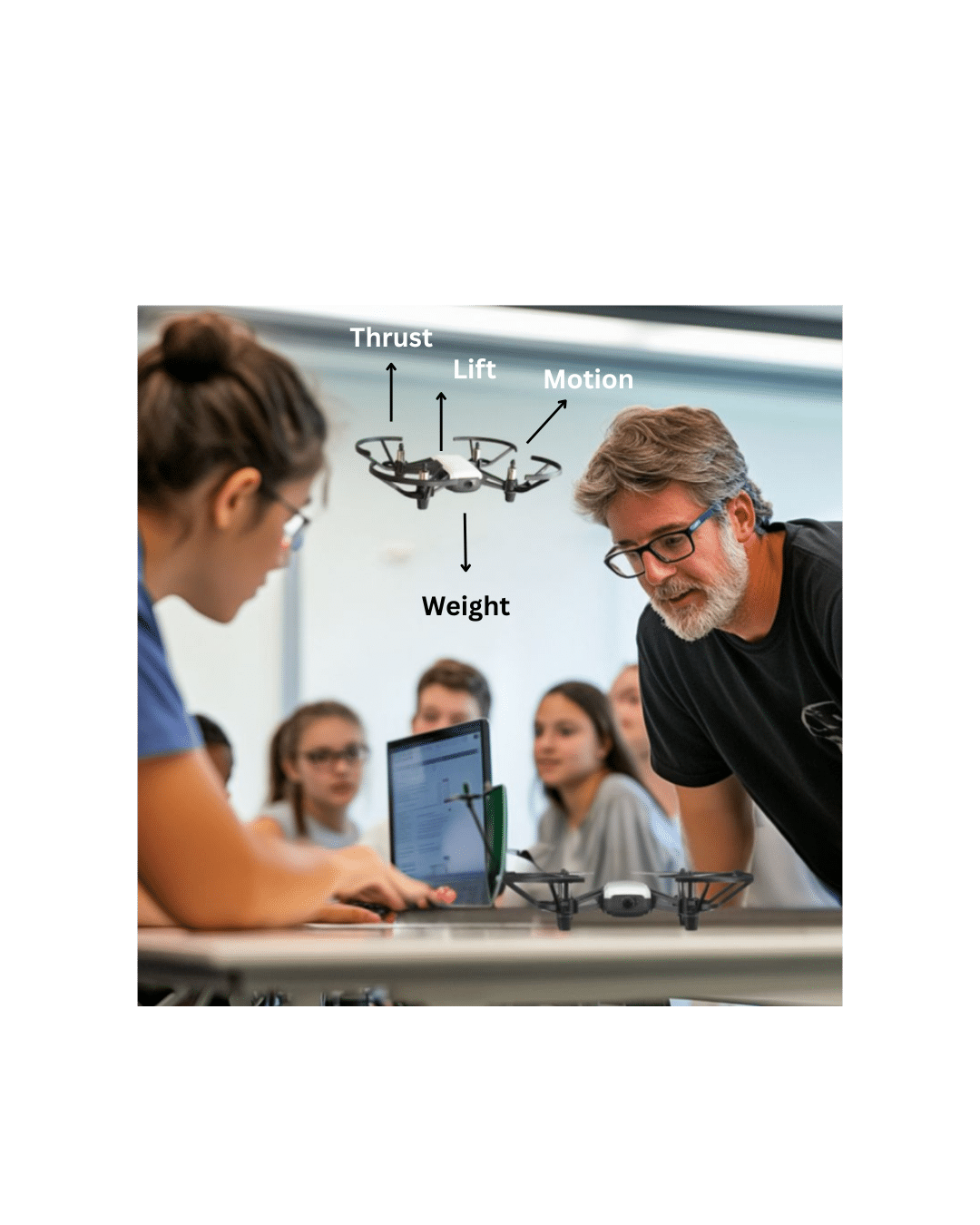

Our STEM robot kits introduce students to the same core ideas behind systems like Dexory: sensors, motion, perception, automation, and collaboration between humans and machines. Students program behavior, analyze data, and understand how autonomous systems operate in real settings with robotics for stem.

Whether schools are building foundational STEM robotics programs or expanding into advanced applications, LocoRobo provides structured curriculum, teacher support, and scalable platforms that mirror how robotics is actually used in industry today.

Automation is not something students will “run into” someday. It is already here. The question is whether they will understand how it works. LocoRobo helps make sure they do.